Filters

What is a CNC tool holder ? Understand 3 selection criteria and 3 key technical points

What is a CNC tool holder ? Understand 3 selection criteria and 3 key technical points To correctly select a...

Read More

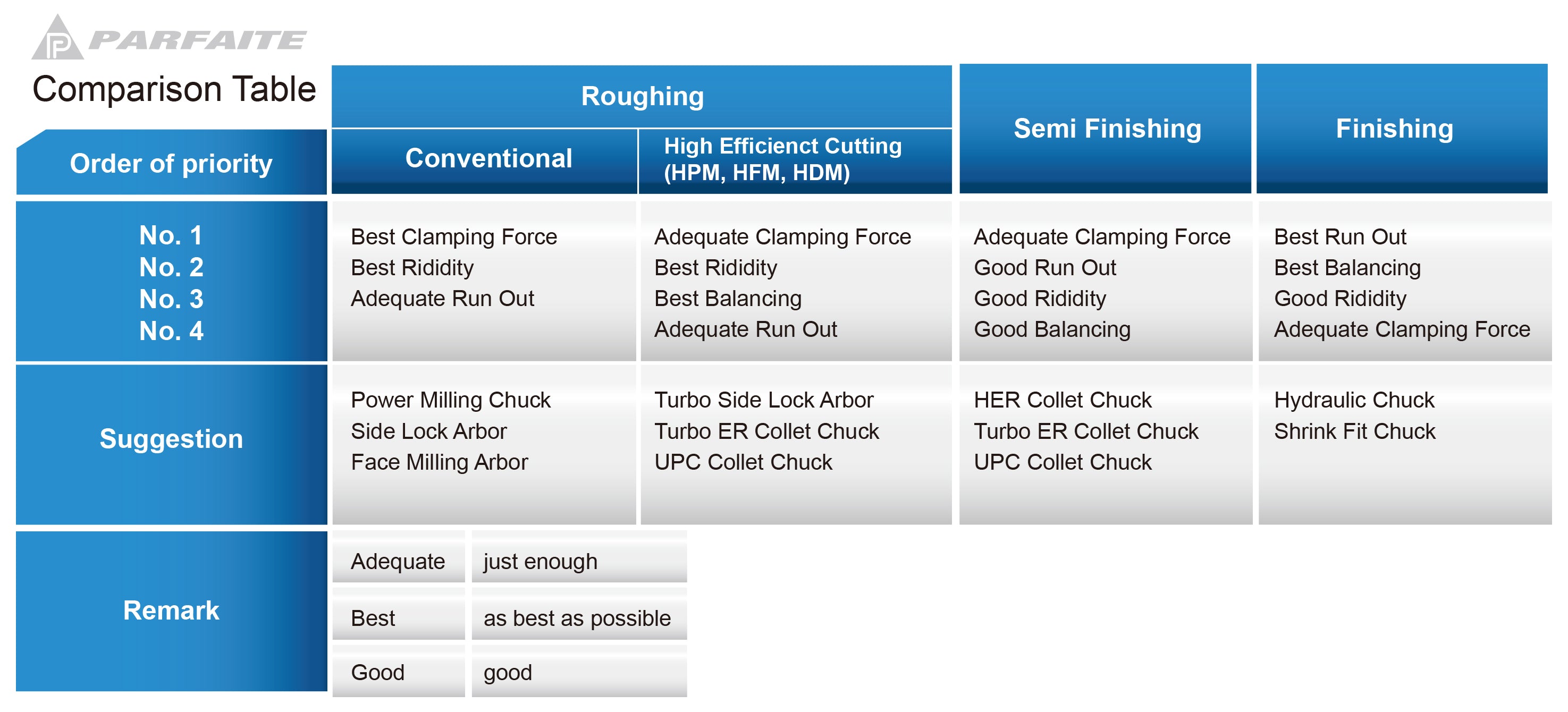

Smart Tool Holder Selection – Choose by Application

3μm-Hydraulic Chuck

You can achieve 3μ processing goal without expensive equipment.

The hydraulic tool handle adopts the locking method of hydraulic expansion technology to quickly reach the high precision requirement of 3µ. And with the damping and vibration reduction performance, it can reduce cutting chatter and improve production efficiency. It is the first choice toolholder for high performance and high precision.

3μm-Shrink Fit Chuck

Realize the dream of all-round high precision machining

The heat-shrinkable tool holder, also known as the sintered tool holder, adopts a heat-shrinkable clamping structure. It uses induction heating to expand the inner hole for tool clamping, and then cools it to achieve the clamping effect. In addition to maintaining Reliable clamping performance at high speeds, reducing the outer diameter of the tool holder improves the anti-interference ability of the tool holder, which is especially suitable for high-speed milling processes with high speed and interference requirements.

5μm-HER collet Chuck

The power of trapezoidal threads

With high rigidity 200Nm super clamping torque and ≤5μm runout high precision characteristics, the HER collet chuck is a high-efficiency tool holder that can be used for heavy cutting and finishing. The clamping torque is 2.3 times larger than the general ER tool holder. The depth of cutting and feeding efficiency can be optimized.